Blog

Do Chinese factories use robots in their operations?

The most widely applied use case in the past was robotic arms on factory production lines, which can replace certain repetitive and patterned operations. This allows for the complete replacement of workers performing repetitive tasks. Given how popular the concept of industrial robots has become, why have only a few large factories deployed them? I believe this can be analyzed from the following aspects:

- High Costs and Limited Adoption

Industrial robots are still considered precision devices, requiring advanced technology and significant research and development investments. As a result, their production costs remain extremely high. Factories without substantial capital find it difficult to deploy industrial robots, and even if they manage to do so, generating economic benefits can be challenging due to the high upfront investment and substantial maintenance costs. For many average factories, industrial robots are still more of a gimmick—prohibitively expensive, deterring many manufacturers from adoption. To enable widespread adoption of industrial robots, entry barriers must be lowered, and maintenance costs need to be reduced. Otherwise, conventional labor-driven manufacturing will continue to dominate for a long time. - Varying Production Needs Across Factories

Every factory has its own products and unique production processes. If robots are to replace human workers, different factories will require customized solutions for their robots. Additionally, each production process differs, necessitating further robot customization. This not only increases costs but also complicates maintenance. As a result, using robots may create more challenges rather than simplifying operations. While large-scale manufacturing enterprises may benefit from increased efficiency, enhanced precision, and improved product yield rates, small and medium-sized enterprises (SMEs) may not experience the same advantages. - Human Workers Are More Flexible Than Robots

Factories deploying robots must invest resources in maintenance. Regardless of whether the order volume is high or low, whether the robots are operating or idle, they occupy space and require maintenance personnel. In contrast, human workers offer greater flexibility. When business is booming, more workers can be hired to meet production demands; when orders decline, fewer workers can be employed, maintaining an optimal production balance. This ability to dynamically adjust labor costs gives human workers an edge over robots. Robots, however, require continuous financial investment regardless of business conditions. - Robots Are Not Yet Capable of Fully Replacing Human Workers

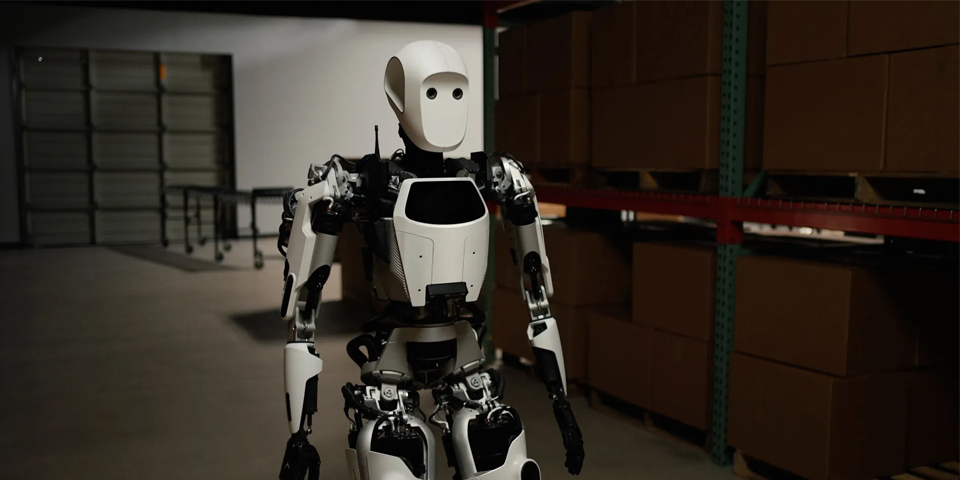

This is a crucial factor. Robots are designed by humans and can only execute tasks based on pre-programmed workflows and commands. However, many real-world tasks require human thought and decision-making, which robots currently struggle to replicate. Human cognition plays a key role in numerous operations, making full automation challenging. Although robots are gradually incorporating artificial intelligence and acquiring limited learning capabilities, they still fall short of human intelligence. Many complex tasks still require human intervention.